Restoring a small mechanism

This page concentrates on the cleaning and restoration of small mechanisms from 18 to 72 notes and is work in progress.

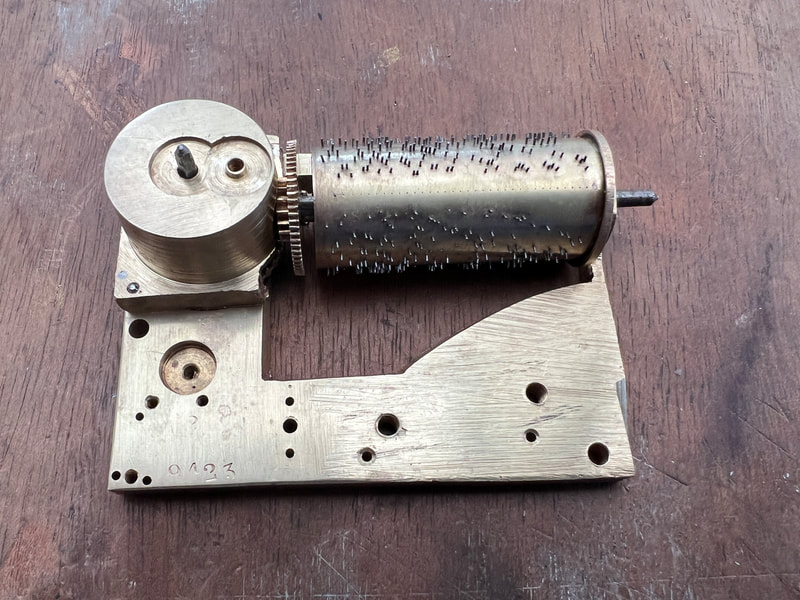

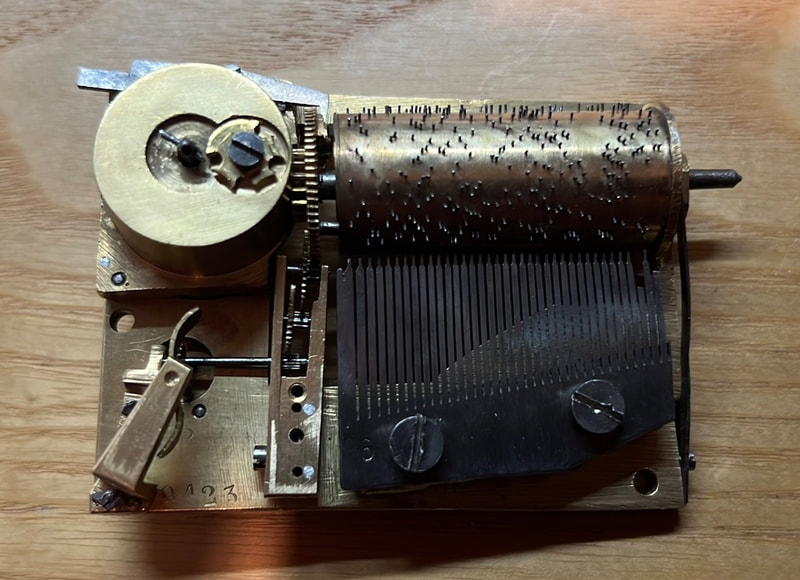

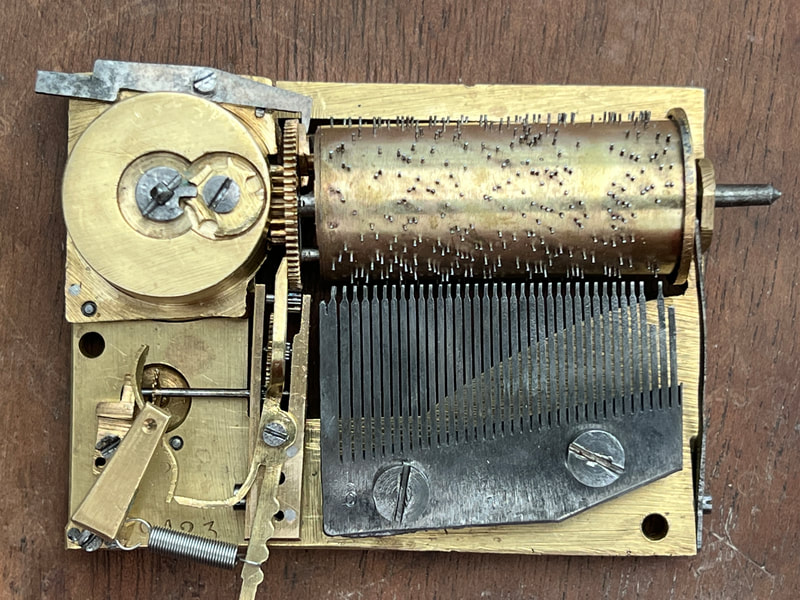

Below is a 3/36 Thorens movement in a Birds Eye Maple box that had seen better days.

Below is a 3/36 Thorens movement in a Birds Eye Maple box that had seen better days.

Much of the process to restore a small mechanism is similar to that of a large cartel.

Start by removing the movement from the case and inspecting it thoroughly for signs of damage.

This movement was particularly dirty and oily with several blobs of some sticky substance on the cylinder and comb.

I'm going to assume that the mechanism runs

Firstly, remove the comb by ending the screws and gently prising the comb plate off the bedplate. There are usually two locator pins in movements of this size.

Then remove the stop mechanism and small spring and allow the spring to run right down.

If the mechanism does not run but the spring is tensioned, care must be taken to avoid damage to the governor cogs.

Wear a thick glove on your non dominant hand, preferably made from leather.

Hold the cylinder tightly with this hand and undo the stop lever screw followed by the screw(s) holding the governor in place.

Gently allow the cylinder to rotate while keeping it's speed in check until the spring is wound down.

Then dismantle the rest of the mechanism completely taking careful note of which screws come from where.

Take lots of photos to refer to later.

Wipe off any surface dirt and oil.

Put all the components, except for the comb, into an ultrasonic bath filled with water and a degreasing agent.

Agitate for as long as it takes to shake off the majority of the dirt.

Remove, rinse and dry everything using paper towels.

Next, using a container with airtight lid, immerse all of the brass components in Horolene.

Follow the directions carefully and always wear a mask and goggles as the solution contains Ammonia.

Put the lid on the container and leave immersed for 12 hours (overnight is good).

Horolene can be used several times, so pour off the liquid into another container with a lid. Label and set aside.

Rinse the components with warm (not hot) water and dry with paper towels.

Start by removing the movement from the case and inspecting it thoroughly for signs of damage.

This movement was particularly dirty and oily with several blobs of some sticky substance on the cylinder and comb.

I'm going to assume that the mechanism runs

Firstly, remove the comb by ending the screws and gently prising the comb plate off the bedplate. There are usually two locator pins in movements of this size.

Then remove the stop mechanism and small spring and allow the spring to run right down.

If the mechanism does not run but the spring is tensioned, care must be taken to avoid damage to the governor cogs.

Wear a thick glove on your non dominant hand, preferably made from leather.

Hold the cylinder tightly with this hand and undo the stop lever screw followed by the screw(s) holding the governor in place.

Gently allow the cylinder to rotate while keeping it's speed in check until the spring is wound down.

Then dismantle the rest of the mechanism completely taking careful note of which screws come from where.

Take lots of photos to refer to later.

Wipe off any surface dirt and oil.

Put all the components, except for the comb, into an ultrasonic bath filled with water and a degreasing agent.

Agitate for as long as it takes to shake off the majority of the dirt.

Remove, rinse and dry everything using paper towels.

Next, using a container with airtight lid, immerse all of the brass components in Horolene.

Follow the directions carefully and always wear a mask and goggles as the solution contains Ammonia.

Put the lid on the container and leave immersed for 12 hours (overnight is good).

Horolene can be used several times, so pour off the liquid into another container with a lid. Label and set aside.

Rinse the components with warm (not hot) water and dry with paper towels.

Using a soft toothbrush apply Wrights Brass Polish to all brass components, rinse and dry again.

Follow the directions carefully and always wear gloves, mask and goggles as the solution contains Ammonia.

Finally, using another soft toothbrush, apply a thin layer of AutoSol. Allow to dry and buff with a soft cloth.

Do the same with the cylinder. Do not allow the solution to get inside so tape or bung any holes.

Buff using a soft (horse hair) shoe brush.

Sometimes it may be necessary to use a glassfibre pen to clean and shine the brass. This is particularly useful when cleaning a one-piece governor that you can't fully dismantle.

Follow the directions carefully and always wear gloves, mask and goggles as the solution contains Ammonia.

Finally, using another soft toothbrush, apply a thin layer of AutoSol. Allow to dry and buff with a soft cloth.

Do the same with the cylinder. Do not allow the solution to get inside so tape or bung any holes.

Buff using a soft (horse hair) shoe brush.

Sometimes it may be necessary to use a glassfibre pen to clean and shine the brass. This is particularly useful when cleaning a one-piece governor that you can't fully dismantle.

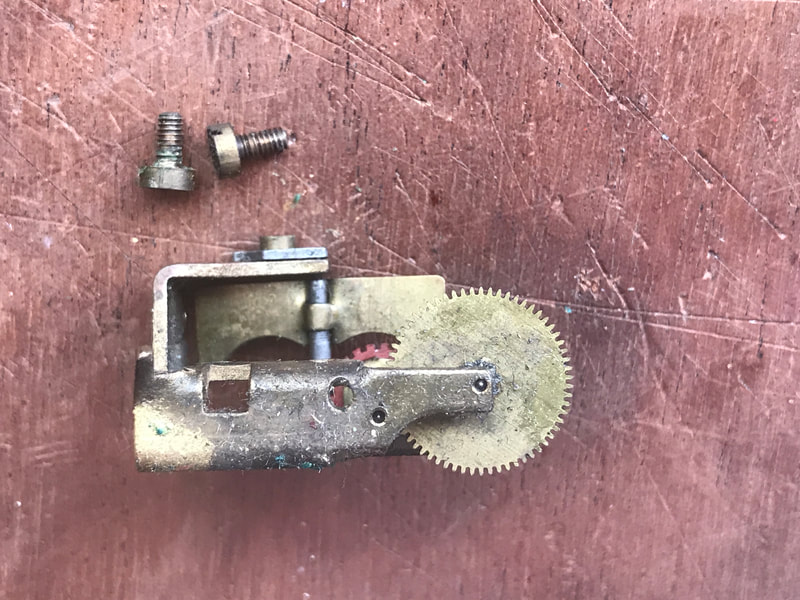

Below are some components from a dismantled 20th century mechanism

Treat the Comb with a lot of respect. The dampers, which are glued to the underside of the bass teeth may be made from quill (part of a feather) and are very vulnerable to damage. Never immerse it, unless you are prepared to replace all of the dampers, either by making new ones from feathers or using modern plastic dampers.

To clean off dirt and rust wipe the top with a degreaser.

Using a flat piece of glass covered with a sheet of the finest emery paper, lay the comb face down on the paper and move it gently back and forth in the direction of the teeth. DO NOT abrade using a side to side motion. It's a good idea to fashion a piece of wedge shaped wood to fit between the comb bed and the dampers so that you put even pressure on the teeth as you rub. Do not over abrade as this might alter the tuning of the teeth.

To clean off dirt and rust wipe the top with a degreaser.

Using a flat piece of glass covered with a sheet of the finest emery paper, lay the comb face down on the paper and move it gently back and forth in the direction of the teeth. DO NOT abrade using a side to side motion. It's a good idea to fashion a piece of wedge shaped wood to fit between the comb bed and the dampers so that you put even pressure on the teeth as you rub. Do not over abrade as this might alter the tuning of the teeth.

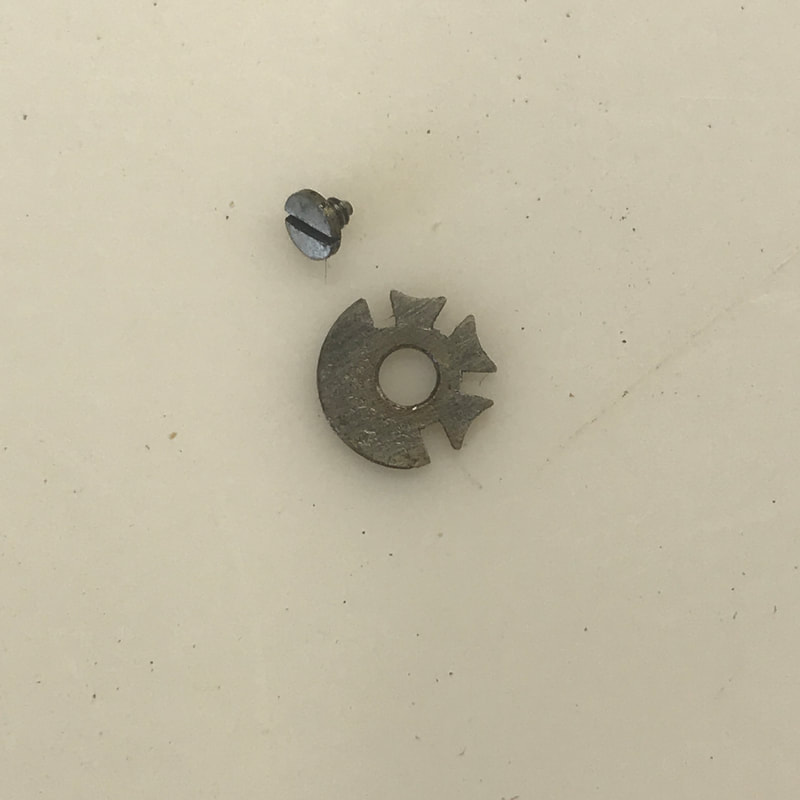

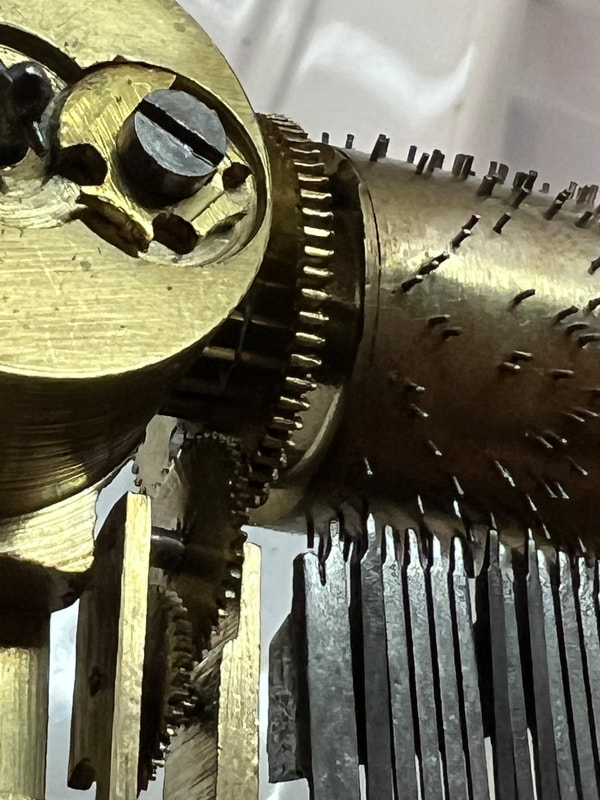

Below are some components from a 19th century mechanism

2/22 Tabatiere movement being cleaned and reassembled