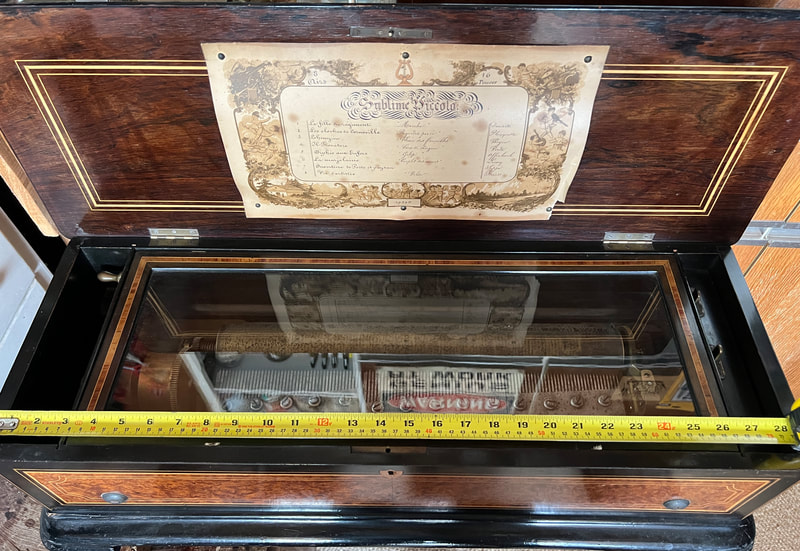

8/130 Cuendet Sublime Piccolo three comb movement Serial no. 19895 circa 1896

Purchased at Auction (unseen) in August 2022. This huge 30' long box appeared to be in relatively good overall condition.

It has three separate combs 44+43+43 and has it's original tune sheet intact.

From the auction photos there appeared to be some damage to the teeth of the great wheel plus it will need a full service and clean plus the restoration of the case.

Images above are from the auction catalogue.

It has three separate combs 44+43+43 and has it's original tune sheet intact.

From the auction photos there appeared to be some damage to the teeth of the great wheel plus it will need a full service and clean plus the restoration of the case.

Images above are from the auction catalogue.

Images taken when it arrived in the workshop below

On arrival I found the springs fully wound and the cylinder stopped part way through a tune.

I moved the cylinder on manually to the rest position for safety sake.

One tooth needs to be repaired and several dampers need replacing.

I moved the cylinder on manually to the rest position for safety sake.

One tooth needs to be repaired and several dampers need replacing.

27th October 2022

I've made a start on restoring this mechanism. It's not good news, except that nothing is missing bar a small spring.

The governor does not run so will require a full rebuild.

Several teeth are damaged on the Great Wheel

There are almost no dampers left on the combs and one tooth needs to be replaced.

Two screws need to be replaced.

Both Geneva stops are damaged, but may be repairable.

One pawl spring is missing - easily replaced.

I've made a start on restoring this mechanism. It's not good news, except that nothing is missing bar a small spring.

The governor does not run so will require a full rebuild.

Several teeth are damaged on the Great Wheel

There are almost no dampers left on the combs and one tooth needs to be replaced.

Two screws need to be replaced.

Both Geneva stops are damaged, but may be repairable.

One pawl spring is missing - easily replaced.

Below is the sequence to take a spring out of its barrel for cleaning using a special jig. This potentially a dangerous operation. Care needs to be taken to ensure that drive and hooks etc are properly engaged and protect gloves and apron are worn.

These two springs are the largest and strongest I've come across to date.

Note: I had to use a smaller spring barrel (see 10 & 11) which had a smaller diameter and thickness to allow me to use the hook system and I have a special arbor made so that I didn't' need to separate the twin arbors.

These two springs are the largest and strongest I've come across to date.

Note: I had to use a smaller spring barrel (see 10 & 11) which had a smaller diameter and thickness to allow me to use the hook system and I have a special arbor made so that I didn't' need to separate the twin arbors.

|

Sunday 27th November

Getting the springs back into the barrels was a tough job, even with the jig used to remove them. Just shows how dangerous the springs can be. Having got them in and greased, there was the challenge of getting the arbor's to engage (and stay engaged, as well as pressing the covers on. Needed a bit of ingenuity, but we got there, Having got the arbors engaged, I decided that I had to add the Geneva stops to prevent them coming apart again. My local friend had made two new male stops to replace the originals which were badly bent. The winder ratchet is 'different' to the norm, and I had to make a new spring for the inside of the handle. It broke, so another has now been made out of brass and works a treat. I've reassembled most of the mechanism, but .... Update January: Too many pins were too badly bent to straighten, especially on the last track, to continue so the whole mechanism has gone to The Music Box Restorer for the cylinder to be re-pinned, restore the three combs, repair the teeth on the Great Wheel and rebuild the governor. I thought we wouldn't see this box back until autumn 2023, but James has done his work in record time and I collected it on 6th July. Very excited to see what he'd done - and hear it for the first time. |

Restoring and polishing the case

Some small pieces of banding had lifted, but no pieces were missing.

A block of smooth oak was microwaved for 1 minute and then clamped over the area with a piece of greaseproof paper between it and the case. This heats and melts to original glue and then lets it reset, gluing the banding back down.

There was a small piece of stringing missing from one end. Easily replaced and fixed using a hide glue then pared down before polishing.

The glass lid was masked and given a coat of black French polish. The top needed double masking to keep the black off of the inlay.

The inside of the case and the external base were also given two coats of black French polish.

The exterior was given a light rub with wire wool dipped in meths to lift the top layer of polish and deposit it into the cracks. Then a light abrading with 400 grit silicon carbide paper before several coats of shellac were applied.

Meanwhile the brass hinges, lock & keep were cleaned and polished. Most of the original brass studs were used to fix the tune sheet back in position and two red strips of leather were fixed to the underside of the glass lid.

A dark red tassel was added to the lock key to finish.

Some small pieces of banding had lifted, but no pieces were missing.

A block of smooth oak was microwaved for 1 minute and then clamped over the area with a piece of greaseproof paper between it and the case. This heats and melts to original glue and then lets it reset, gluing the banding back down.

There was a small piece of stringing missing from one end. Easily replaced and fixed using a hide glue then pared down before polishing.

The glass lid was masked and given a coat of black French polish. The top needed double masking to keep the black off of the inlay.

The inside of the case and the external base were also given two coats of black French polish.

The exterior was given a light rub with wire wool dipped in meths to lift the top layer of polish and deposit it into the cracks. Then a light abrading with 400 grit silicon carbide paper before several coats of shellac were applied.

Meanwhile the brass hinges, lock & keep were cleaned and polished. Most of the original brass studs were used to fix the tune sheet back in position and two red strips of leather were fixed to the underside of the glass lid.

A dark red tassel was added to the lock key to finish.

Note: The box overhanging the bench is on a turntable that allow it to be rotated so that all four sides can be treated with shellac in turn. The process is continuous until the desired level of shine is reached.

See the finished box

See the finished box