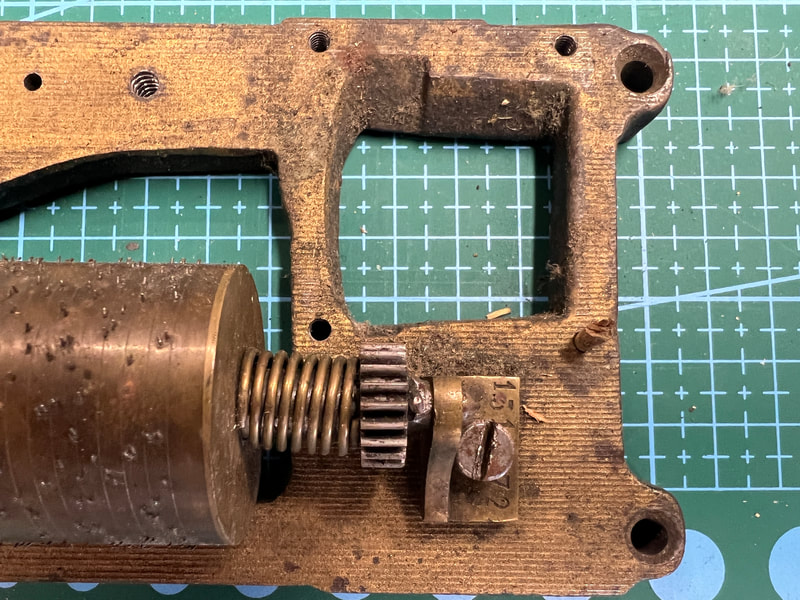

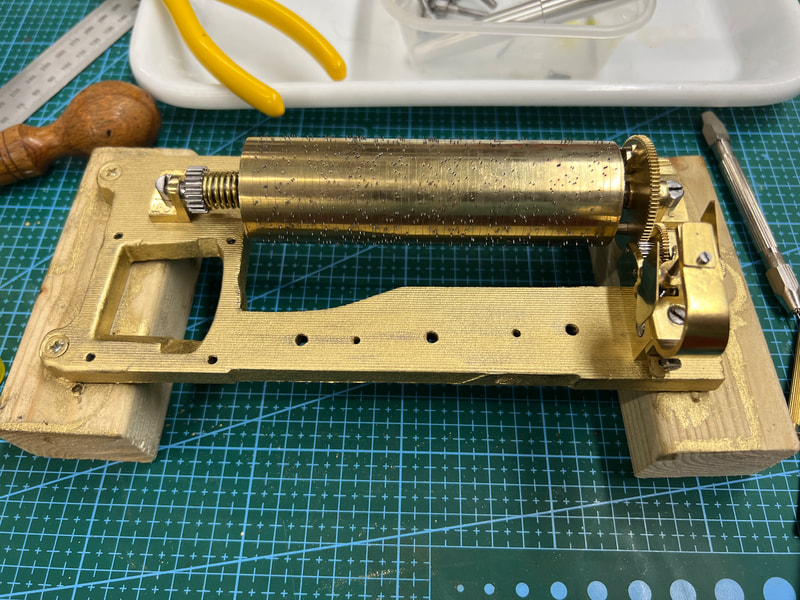

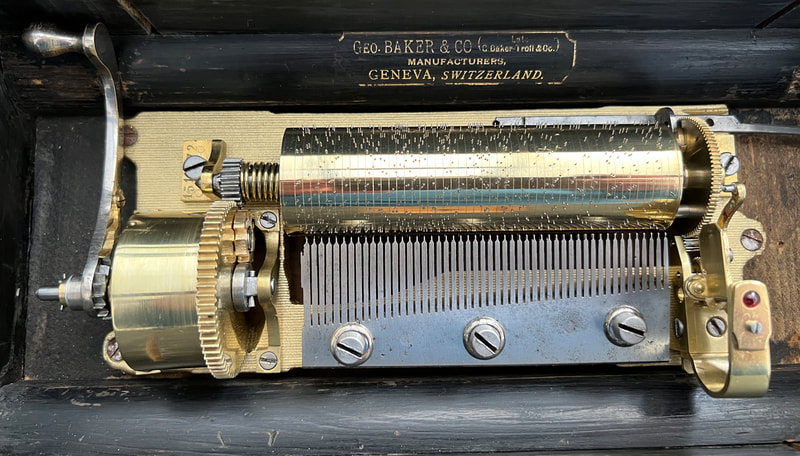

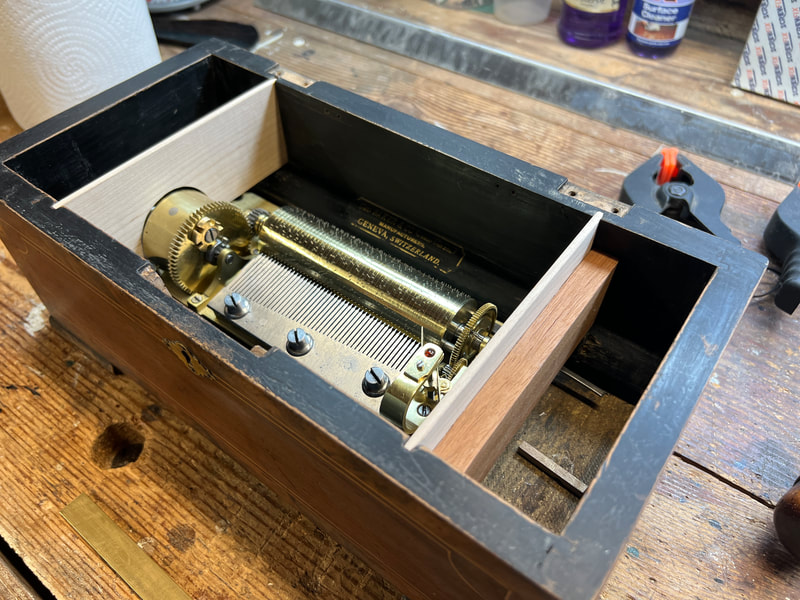

4/50 George Baker Cartel - Serial no 15172 - circa 1895

Bought at auction in March 2022 for £110, mainly because I liked the box and thought it might be a good project to try out some new skills. This little box has seen some life, and abuse, over the years.

Although there appeared to be nothing really seriously wrong with the movement, the following issues needed to be addressed:

There are a lot of badly bent pins. So many are missing or broken that the cylinder needs to be re-pinned.

The amount of oil and grease was very difficult to eradicate.

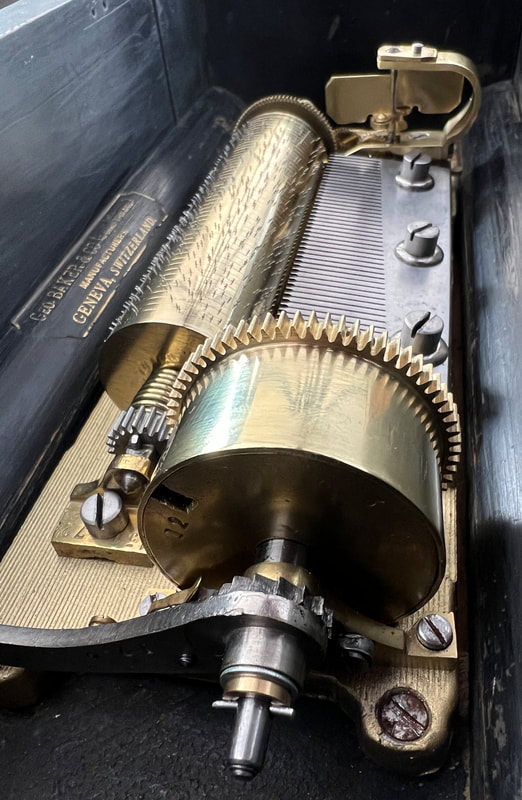

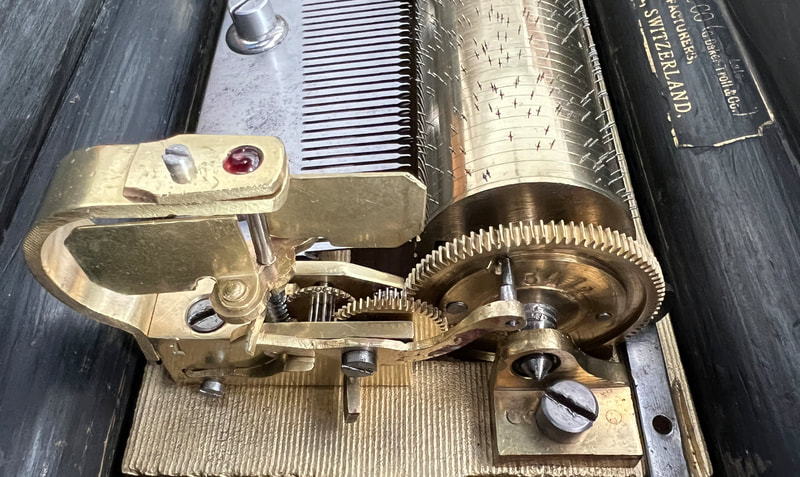

The governor arm had lost both locating pins.

There was no end stone, bearing plate or screw for the governor.

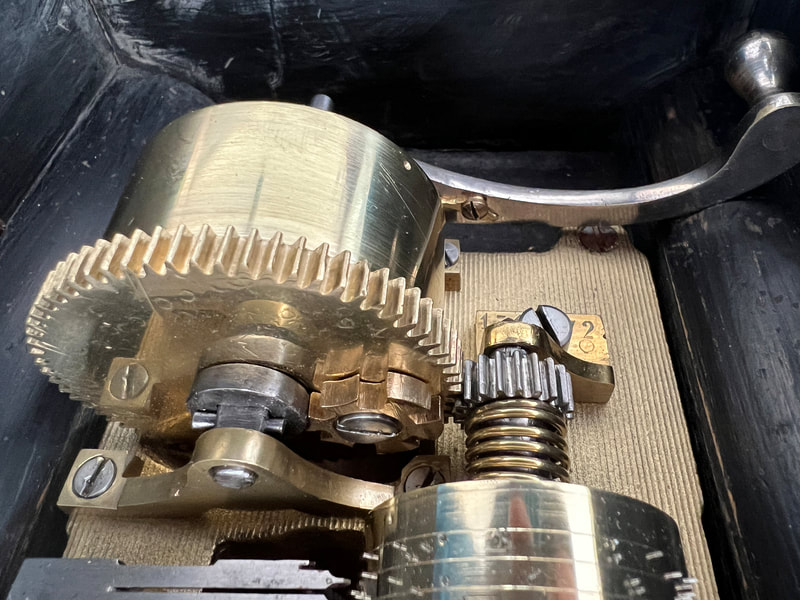

The winding lever was bent.

The female Geneva Stop and screw were missing.

Both pawl springs were missing - easily fixed.

One spring motor bearing screw was missing.

The change lever had been broken and subsequently shortened, but still works

It's obvious that the mechanism has been taken to pieces many, many times using poor tools so many of the screws were damaged.

The good news is that the main spring was in good order and, apart from the Geneva Stop and bearing screw, I can make all the smaller pieces required myself.

There are a lot of badly bent pins. So many are missing or broken that the cylinder needs to be re-pinned.

The amount of oil and grease was very difficult to eradicate.

The governor arm had lost both locating pins.

There was no end stone, bearing plate or screw for the governor.

The winding lever was bent.

The female Geneva Stop and screw were missing.

Both pawl springs were missing - easily fixed.

One spring motor bearing screw was missing.

The change lever had been broken and subsequently shortened, but still works

It's obvious that the mechanism has been taken to pieces many, many times using poor tools so many of the screws were damaged.

The good news is that the main spring was in good order and, apart from the Geneva Stop and bearing screw, I can make all the smaller pieces required myself.

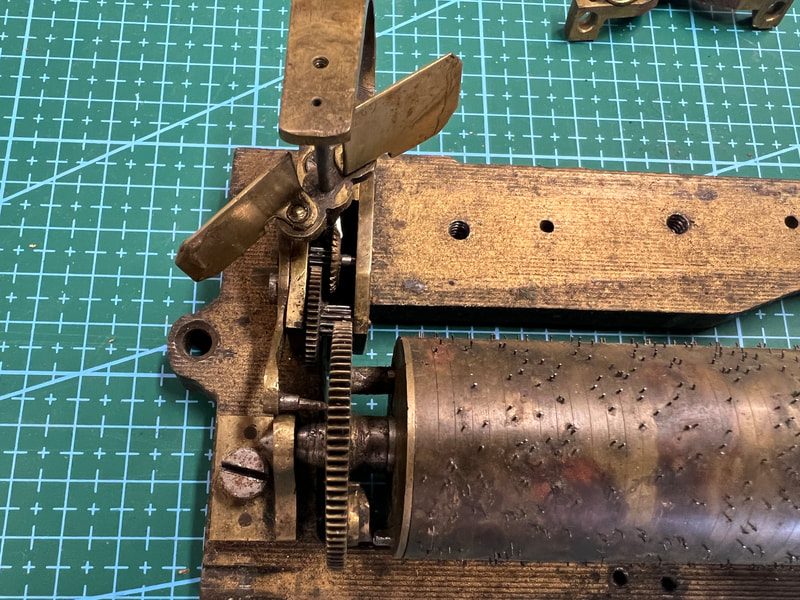

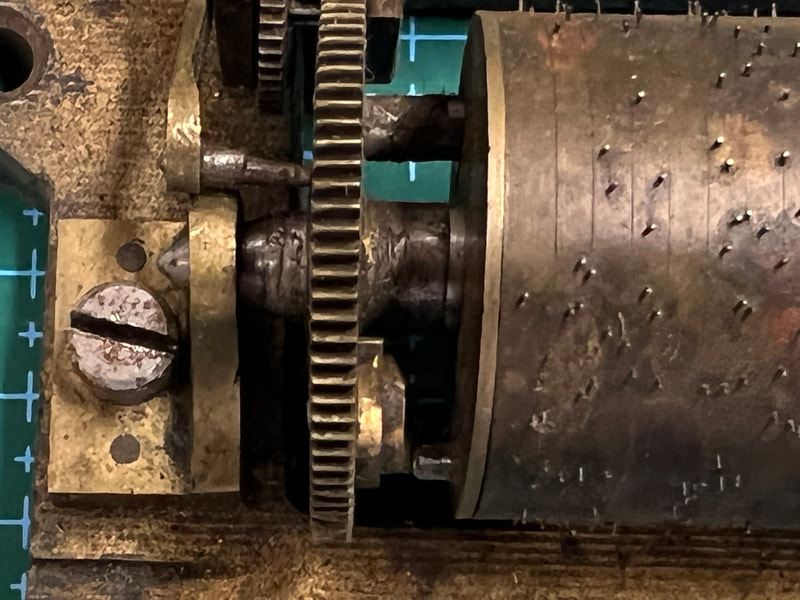

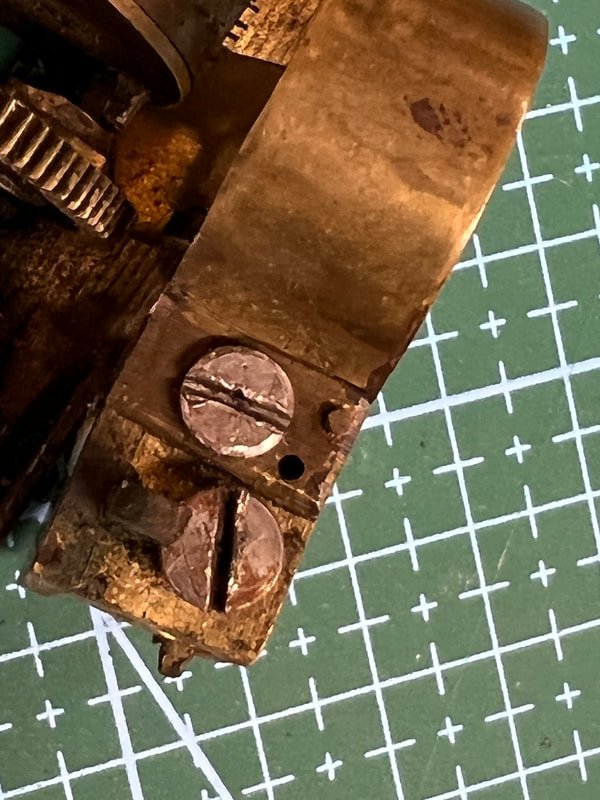

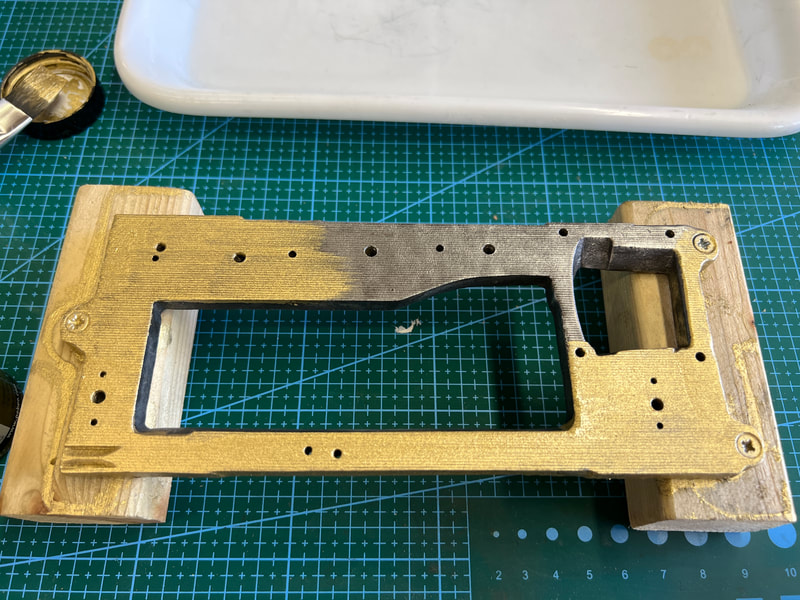

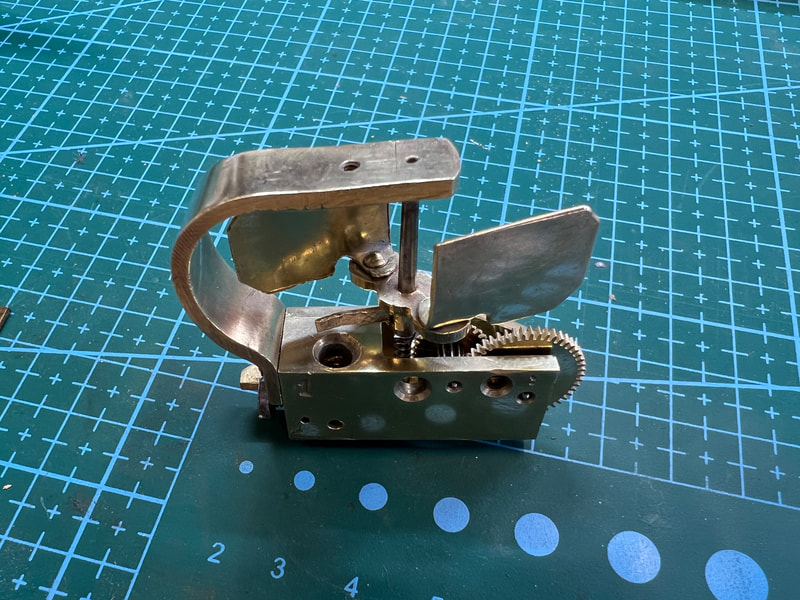

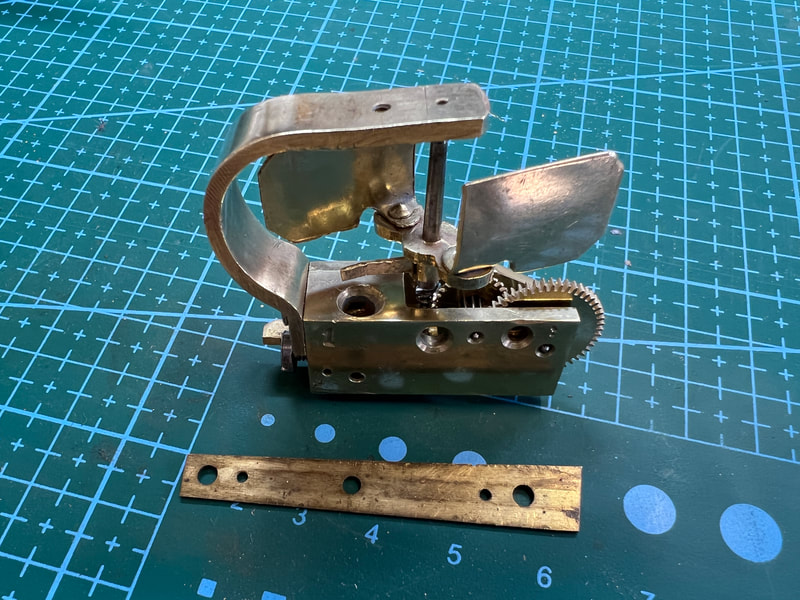

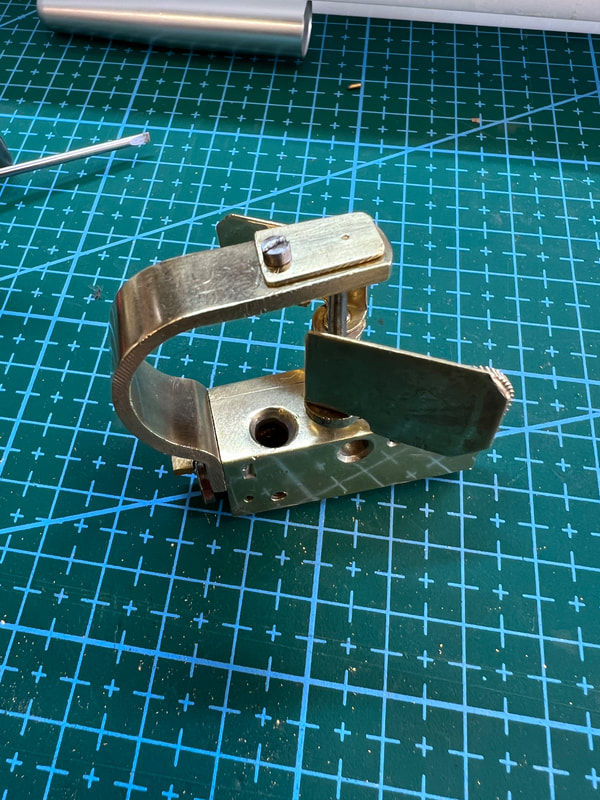

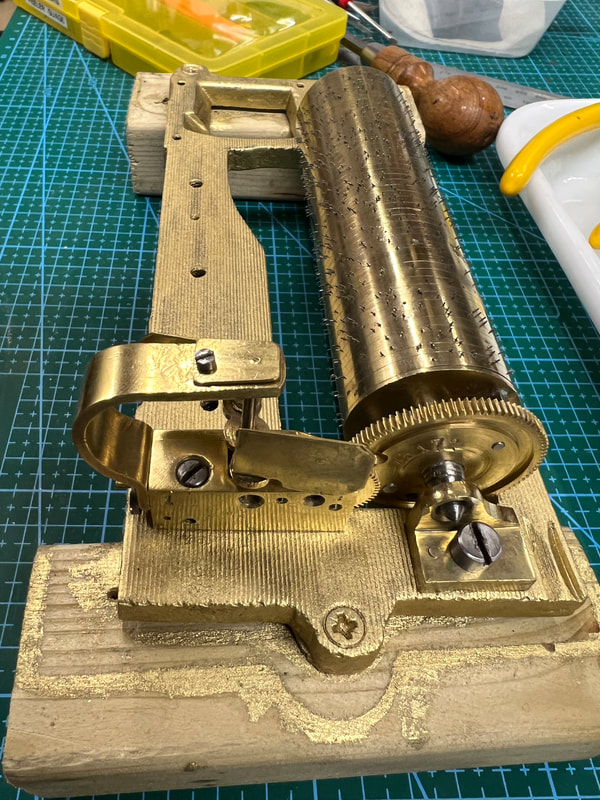

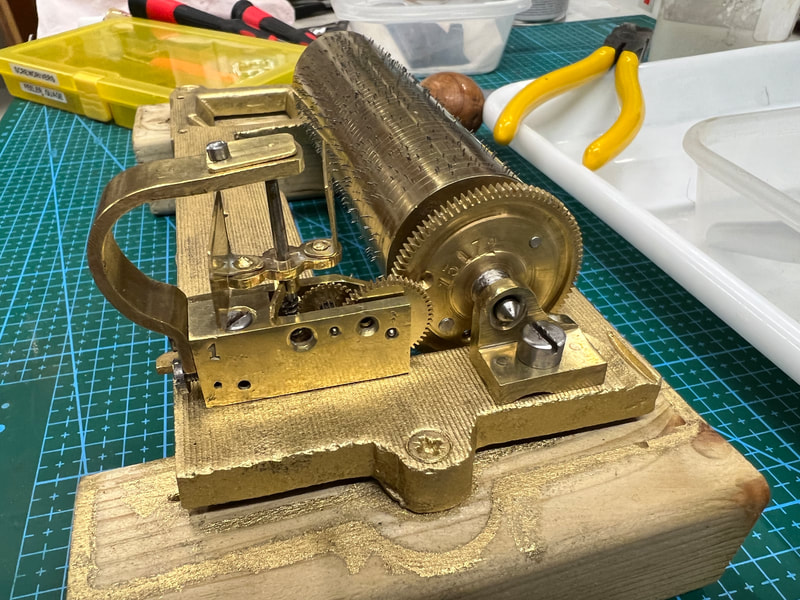

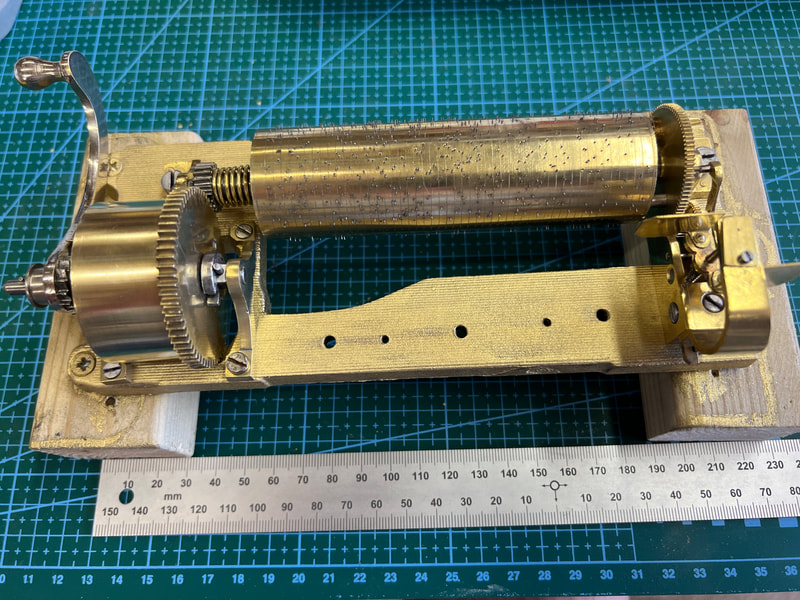

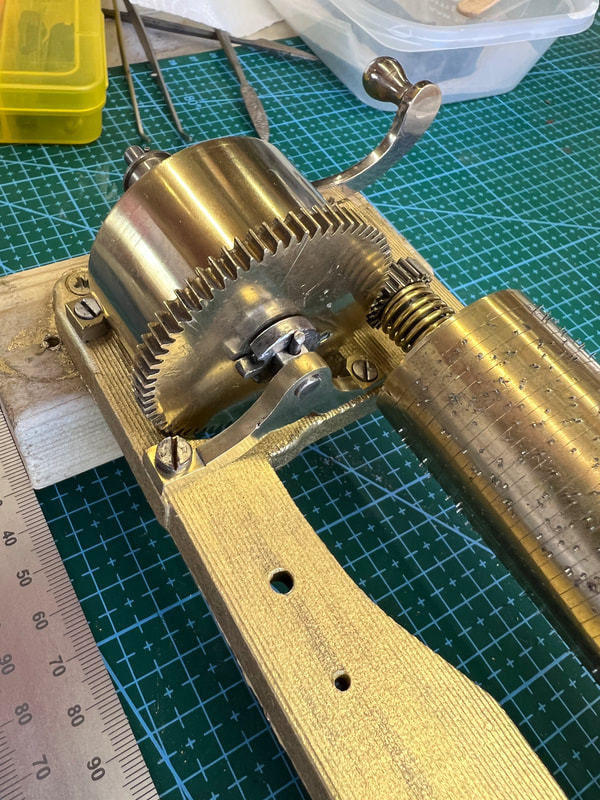

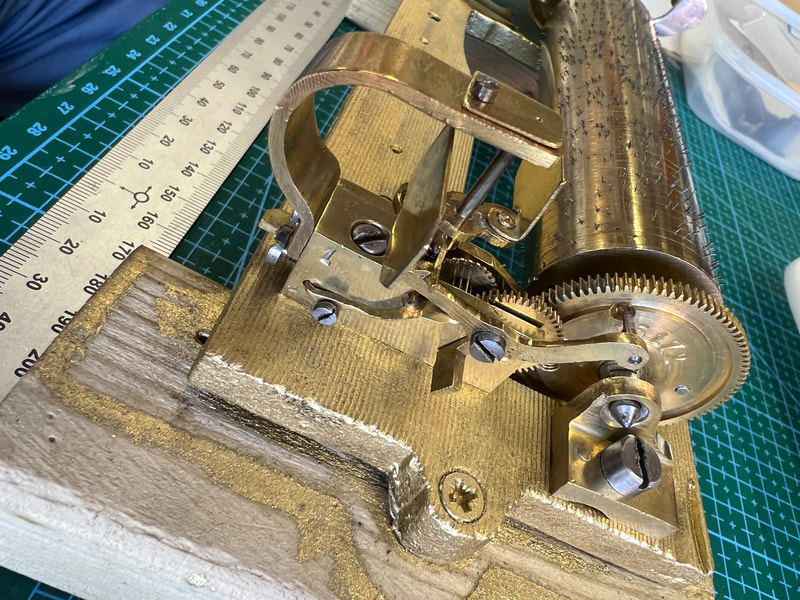

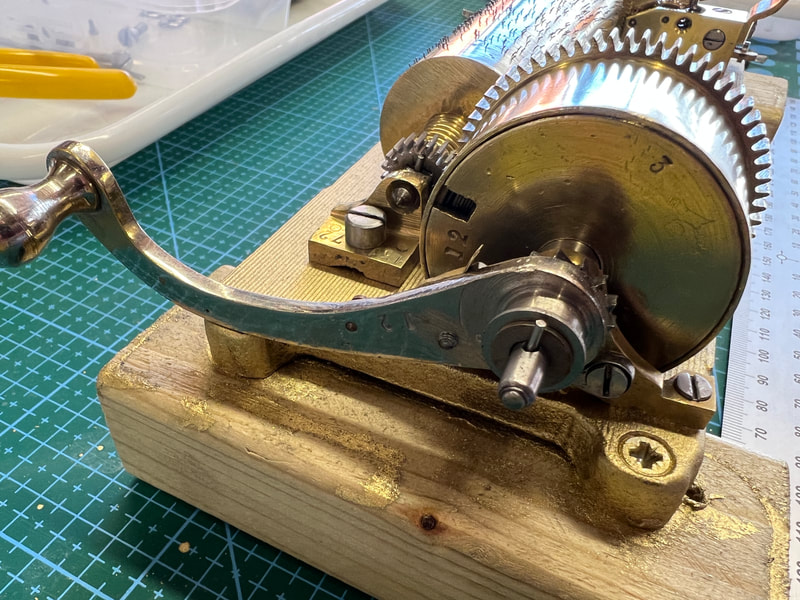

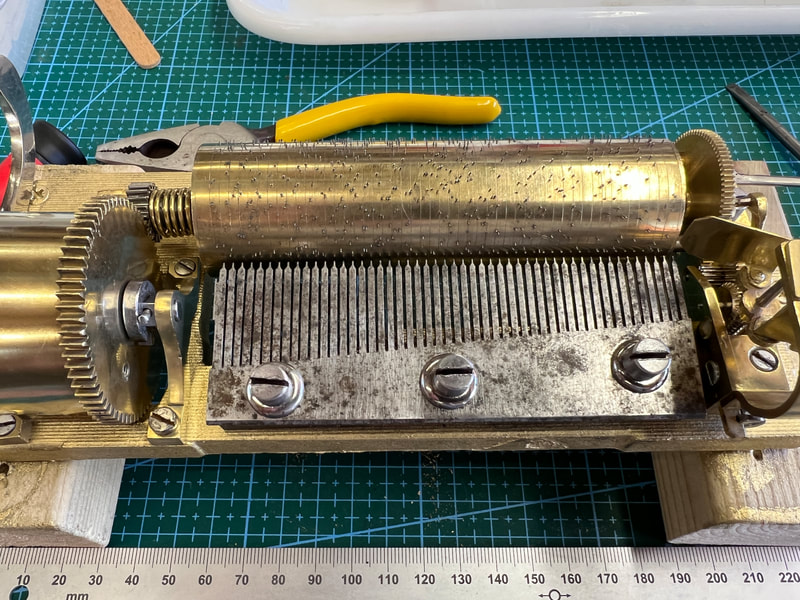

Above images show the cleaning process and the start of making some of the missing components.

The two pawl springs were fashioned out of brass sheet, cut and filed to shape and drilled for the screw fixing then the spring end hammered flat. Attached using the original screws.

The two pawl springs were fashioned out of brass sheet, cut and filed to shape and drilled for the screw fixing then the spring end hammered flat. Attached using the original screws.

The images above show the transformation but, apart from those identified above, there are still some issues that need to be addressed.

The loss of pins exceeds 10% and there is a gouge in the side of the cylinder which can be seen in the short video below.

The spring casing cover is loose and will not stay in place.

The comb needs to be de-rusted and all of the dampers need to be replaced.

I have decide to have all of this work done by The Music Box Restorer

The loss of pins exceeds 10% and there is a gouge in the side of the cylinder which can be seen in the short video below.

The spring casing cover is loose and will not stay in place.

The comb needs to be de-rusted and all of the dampers need to be replaced.

I have decide to have all of this work done by The Music Box Restorer

|

The good news is that the mechanism runs well, which is especially gratifying as there is no governor bearing jewel, just a temporary cover, so it should run even better with that in place.

|

|

2nd February 2023

Fresh back from The Music Box Restorer and running like a bird!

Fresh back from The Music Box Restorer and running like a bird!

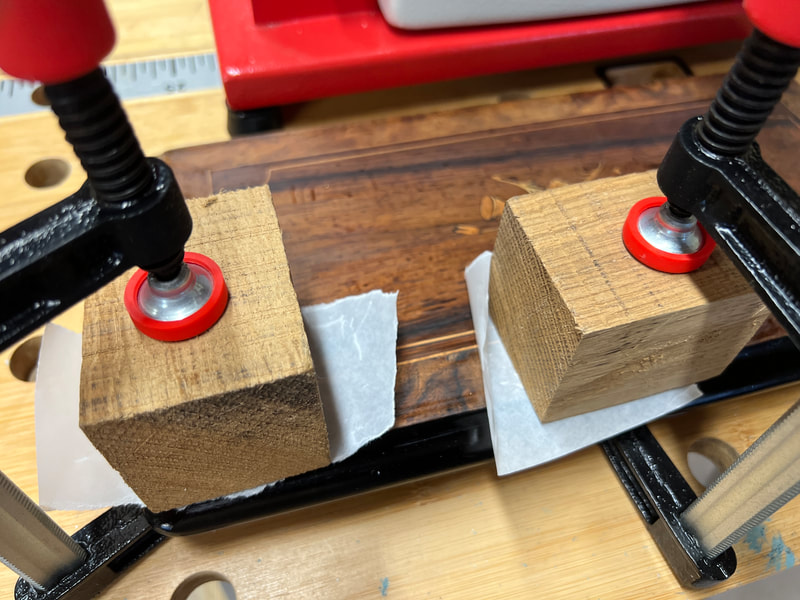

On the up side, the case is in really good condition, though there were several veneer bubbles in the lid. These were quickly put right using two blocks of oak, heated in the microwave for a minute then clamped over the bubbles with some wax paper between them to prevent sticking. Hey presto, no bubbles!

I then used 0000 gauge wire wool dipped in meths to go over all the surfaces. This lifts off all the dirt and fills the smaller cracks. A rub down with 400 grit silicon carbide paper and it's ready for polishing.

I then used 0000 gauge wire wool dipped in meths to go over all the surfaces. This lifts off all the dirt and fills the smaller cracks. A rub down with 400 grit silicon carbide paper and it's ready for polishing.

March 2023

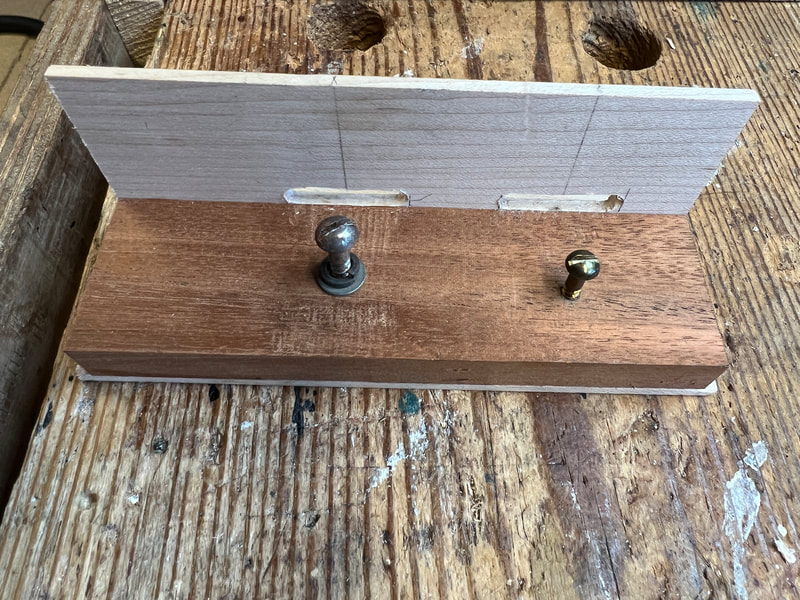

The original two dividers that slot into the box at either end of the mechanism were missing, as were the two brass control levers.

Below are pictures of me making new ones.

The original two dividers that slot into the box at either end of the mechanism were missing, as were the two brass control levers.

Below are pictures of me making new ones.

So now we are on to polishing. First black French polish brushed on - two coats

First coats of shellac. When dry all will be lightly abraded with 400 grit silicon carbide paper and then re polished with more shellac

The finished item, except for the replica tune sheet which will follow soon.