Above, I finished my part of this restoration, before taking the box to The Musicbox Restorer to have a tooth replaced and the dampers sorted. It's back from this work but having given it a final polish, I've now sent the governor to be professionally repaired as it was impossible to make it run at the right speed.

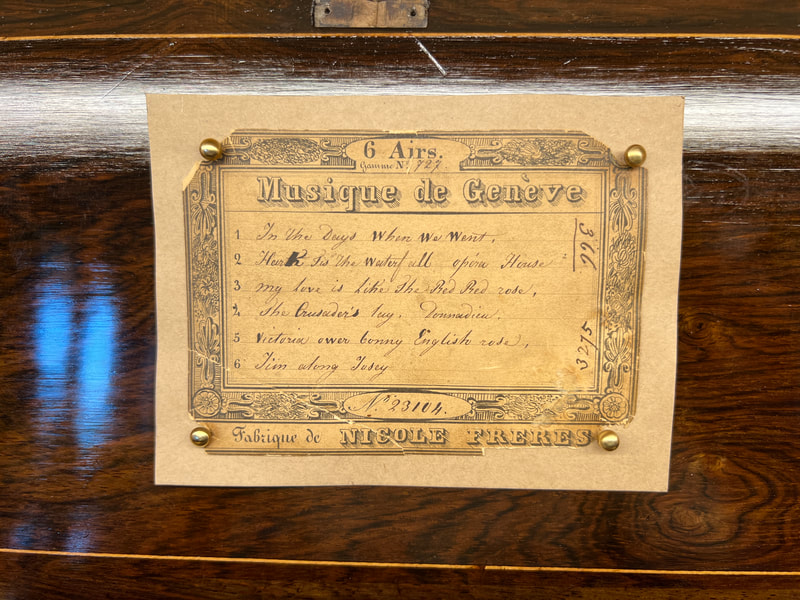

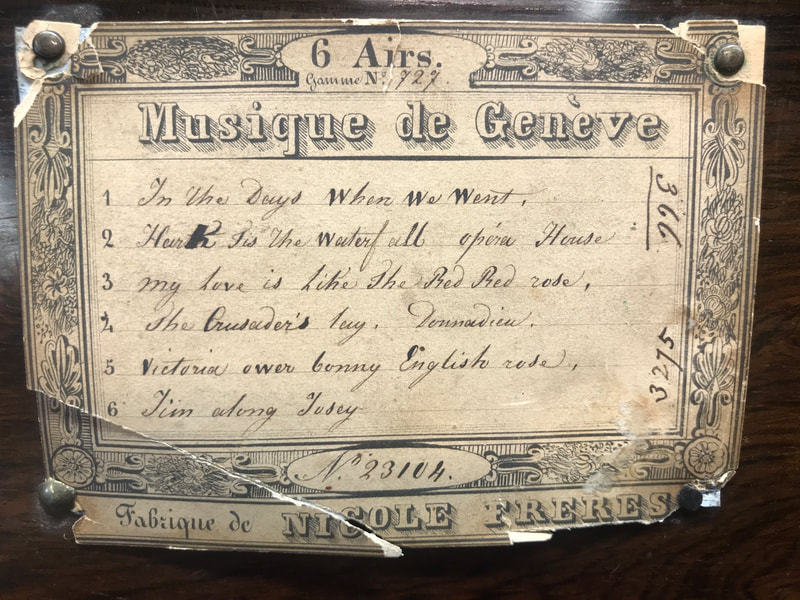

6/104 Nicol Freres Cartel circa 1844, Serial no. 23104

Below is the first set of images after collecting this cartel from the auction house. It went straight into the workshop.

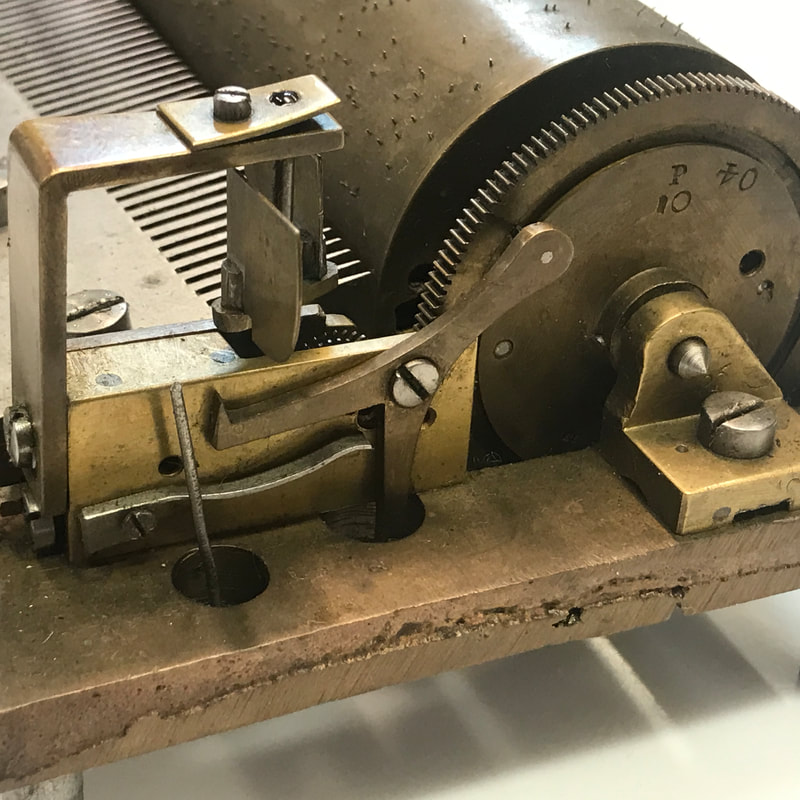

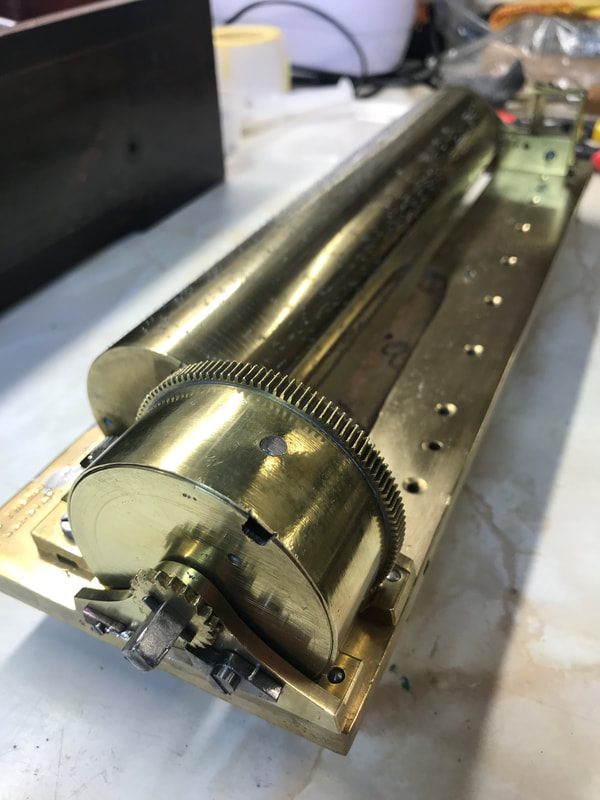

The pictures above show the box and mechanism before visual inspection

The case is in fabulous condition for one that is nearly 180 years old

I found several things wrong with the movement that will need to be addressed

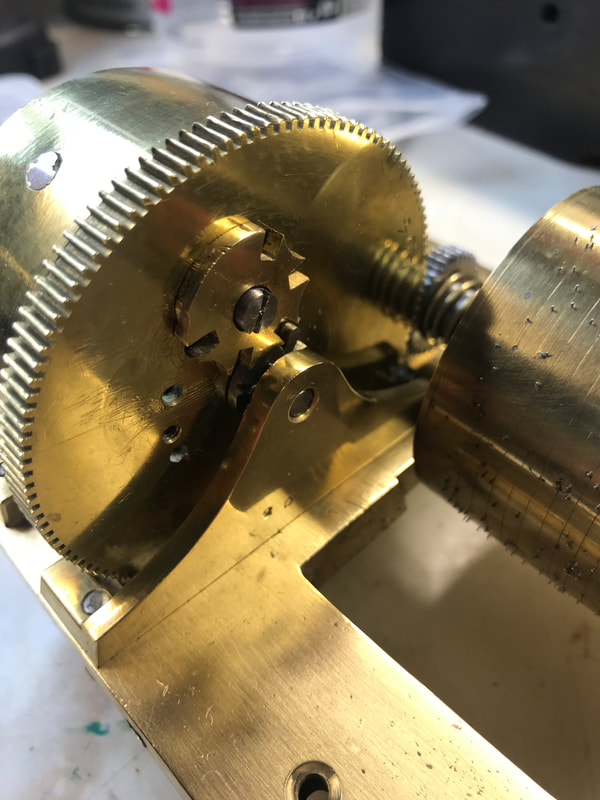

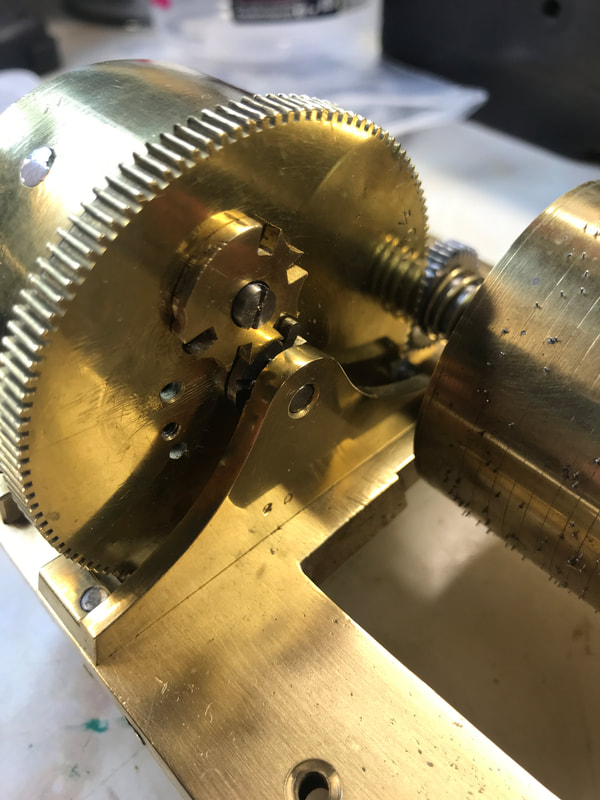

The winder pawl spring is broken off, the pawl screw thread is stripped and the ratchet teeth are badly worn

The spring motor drive wheel has two damaged teeth and the cover has been taken off and refitted in the wrong place

One of the Governor gears has several bent teeth and the vanes are very loose

The jewel bearing is missing (but I have a new one in stock)

The Geneva Stop mechanism is worn, the screw is bent and may not be the original

There is one tooth and several dampers missing from the comb (to be sorted by The Music Box Restorer later in 2022)

The good news is that nothing else is missing and the cylinder is in excellent shape with only a few bent pins.

The case is in fabulous condition for one that is nearly 180 years old

I found several things wrong with the movement that will need to be addressed

The winder pawl spring is broken off, the pawl screw thread is stripped and the ratchet teeth are badly worn

The spring motor drive wheel has two damaged teeth and the cover has been taken off and refitted in the wrong place

One of the Governor gears has several bent teeth and the vanes are very loose

The jewel bearing is missing (but I have a new one in stock)

The Geneva Stop mechanism is worn, the screw is bent and may not be the original

There is one tooth and several dampers missing from the comb (to be sorted by The Music Box Restorer later in 2022)

The good news is that nothing else is missing and the cylinder is in excellent shape with only a few bent pins.

Refurbishing the Movement

Below are the stages of cleaning:

Stage 1

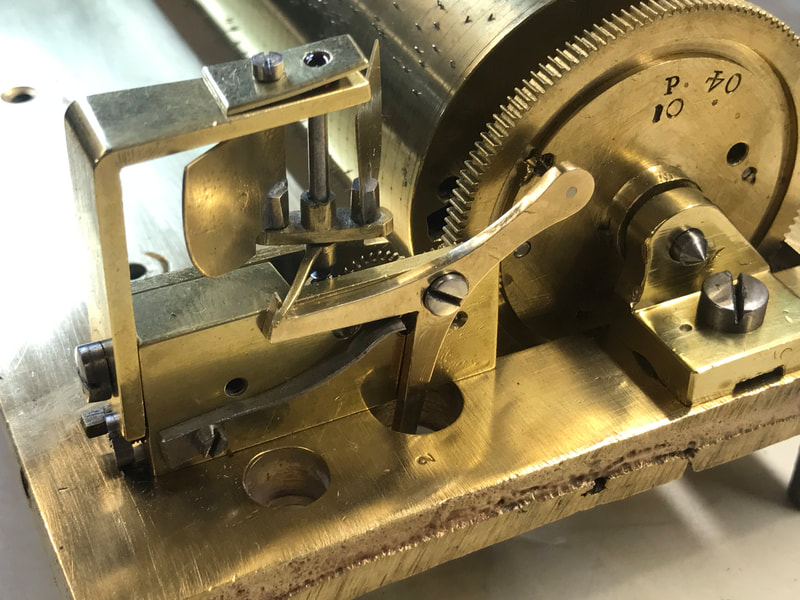

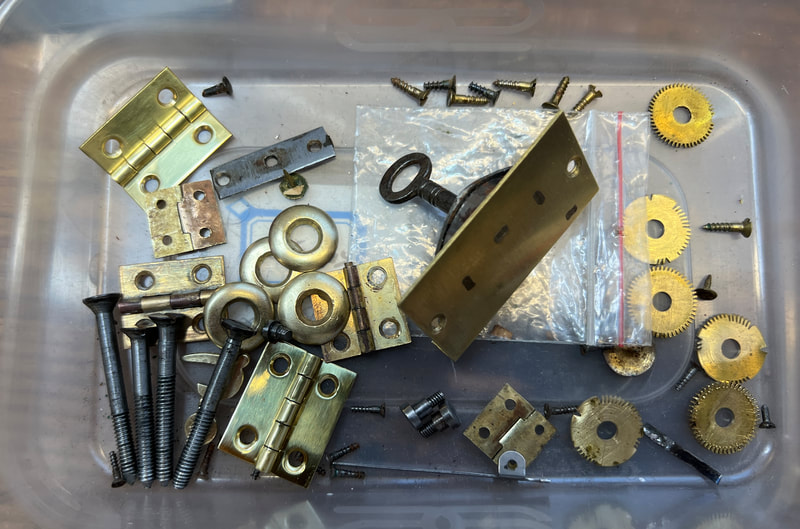

Everything is dismantled and inspected for wear or faults, then carefully put into separate trays.

Comb (separate from screws), Spring Motor parts, Governor parts, Arbour & Cylinder parts, Control mechanism screws, so that they are easier to marry up again later.

The smaller brass parts are then put into a clock cleaner called Horolene and left overnight.

All steel parts are cleaned using a paper towel. The towel is dipped into WD40 degreaser if necessary. Then they are rubbed with 0000 grade wire wool or a fine wire brush to remove all dirt & oil deposits.

The spring is wiped clean prior to being rewound into the motor case where it will be treated with Horoglide.

Stage 2

All brass parts are treated with Wrights Brass Cleaner. This is an ammonia based cream applied with a soft toothbrush.

I wear a mask, eye protection, gloves and apron while applying and brushing off under warm water.

The bottom row of images show the result of about two hours work, which doesn't include the cylinder.

Stage 3

The cylinder is mounted in a purpose made cradle and all the holes in the ends are taped to prevent cleaner or water getting inside. This is then given the same Wrights treatment before being washed in warm water taking care not to get water inside the cylinder. It is then buffed using a fine horsehair brush taking care not to bend any pins.

Stage 1

Everything is dismantled and inspected for wear or faults, then carefully put into separate trays.

Comb (separate from screws), Spring Motor parts, Governor parts, Arbour & Cylinder parts, Control mechanism screws, so that they are easier to marry up again later.

The smaller brass parts are then put into a clock cleaner called Horolene and left overnight.

All steel parts are cleaned using a paper towel. The towel is dipped into WD40 degreaser if necessary. Then they are rubbed with 0000 grade wire wool or a fine wire brush to remove all dirt & oil deposits.

The spring is wiped clean prior to being rewound into the motor case where it will be treated with Horoglide.

Stage 2

All brass parts are treated with Wrights Brass Cleaner. This is an ammonia based cream applied with a soft toothbrush.

I wear a mask, eye protection, gloves and apron while applying and brushing off under warm water.

The bottom row of images show the result of about two hours work, which doesn't include the cylinder.

Stage 3

The cylinder is mounted in a purpose made cradle and all the holes in the ends are taped to prevent cleaner or water getting inside. This is then given the same Wrights treatment before being washed in warm water taking care not to get water inside the cylinder. It is then buffed using a fine horsehair brush taking care not to bend any pins.

|

So, when this music box arrived, because of the damaged governor cog, I could not listen to it play.

With everything cleaned and polished, spring cleaned and oiled, a new governor cog, pawl spring, Geneva stop screw and bearing jewel, it's time to get the mechanism working and hear the music. Click to image to hear "In the Days When We Went" Click here for all the tunes |

|

Refurbishing the box

The Box needs a clean and polish, or so I thought.

Lots of brass cleaning. Replacement lock key, New keyhole inlay, Re-glue two corners of the lid. Lock keep requires a new pin.

Rub down with wire wool and meths which didn't do the job so it's going to be serious. Thank goodness the box is solid timber and not veneered. I've sanded the exterior back to bare wood to remove all the knocks and bumps then using silicon carbide paper sanded to a fine surface then one coat of African Rosewood stain to all surfaces, except for the lid, and left to dry overnight.

Lots of brass cleaning. Replacement lock key, New keyhole inlay, Re-glue two corners of the lid. Lock keep requires a new pin.

Rub down with wire wool and meths which didn't do the job so it's going to be serious. Thank goodness the box is solid timber and not veneered. I've sanded the exterior back to bare wood to remove all the knocks and bumps then using silicon carbide paper sanded to a fine surface then one coat of African Rosewood stain to all surfaces, except for the lid, and left to dry overnight.

After sanding there were still a few small dents and holes to fill. I used a soldering gun to drop hot brown wax into the hole. This is left to go hard and is then scraped off using a sharpened plastic spreader - the typed used for tile grout - which leaves an almost invisible mend.

Finally the box has had three coats of shellac polish and is looking spectacular.

Finally the box has had three coats of shellac polish and is looking spectacular.

This evening I've reassembled the box and given the top of the lid two coats of shellac polish. One more rub down and final coat in the morning and it's finished and ready for the conserved tune sheet to be added to the lid and then it can move into the house.

Above: The final touches - Tune sheet attached and the red tassel for the key.

I decided to have The Musicbox Restorer restore the comb as it was missing on tip and several dampers.

Below is the finished box having dismantle the movement again to polish the brass as it's begun to tarnish due to handling.

Below is the finished box having dismantle the movement again to polish the brass as it's begun to tarnish due to handling.